Welded Rupture Disk Advantages in Sanitary Applications

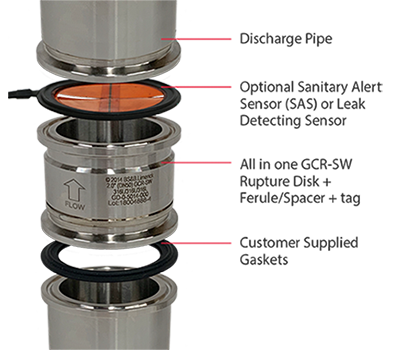

BS&B type GCR-SW assembly

Sanitary/hygienic rupture disks with integral gaskets have long been the industry standard and were state of the art 30 years ago. Many customers are discovering the benefits of contemporary technology where welded assemblies can be used to address the limitations of these legacy products.

Advantage 1: Integrated Components

The inlet, rupture disk, and outlet components are welded together. This design isolates and protects the rupture disk from uneven or improper loads due to pipe misalignment or improper torque.

Advantage 2: Easier Installation and Increased Versatility

A one-piece design allows for easier handling and clamping and quick removal once activated based on the non-fragmenting petal being contained within the assembly. Standard gaskets and clamps may be used and the disk can be removed and replaced multiple times with no detrimental effect on performance or service life.

Advantage 3: Simplified Management of Change

Existing BS&B sanitary disks can be upgraded without any additional sizing calculations since welded assemblies have identical flow characteristics and certifications.

Advantage 4: Consolidation Opportunities

Similar specifications of disks with different gasket materials can be replaced with a single welded assembly. Inventory is reduced and larger quantities can be ordered for additional savings.

Advantage 5: Less Susceptible to Damage, Longer Service Life

The disk dome is completely covered by the inlet component of the device. No attached gaskets means no temperature limits, allowing for these disks to be autoclave sterilized or otherwise exposed to service temperatures well above the limits of elastomers gaskets.