ASME Certified Rupture Disk

The Basics of ASME Rupture Disk Code

In the United States of America, the most common rupture disk certification we encounter is ASME. ASME stands for American Society of Mechanical Engineers, founded in 1880 the origination oversees their own set of standards. The section of the ASME Boiler and Pressure Vessel Code that pertains to rupture disks is Section XIII, Rules for Overpressure Protection. There are also aspects of Section III (nuclear) which are also relevant to use of rupture disks and it is worth noting that Section I, which deals with direct fired boilers, disallows the use of rupture disks as a means of overpressure protection.

There are many provisions of this Code that apply to rupture disks. Some are recommendations, some are Code mandatory, and some are technical guidance such as sizing methodologies. Additionally, The Code obligates rupture disk manufacturers who wish to provide ASME Compliant rupture disks to the marketplace to have each facility and each product from those facilities certified by ASME’s designated authorization body, the National Board of Boiler and Pressure Vessel Inspectors (typically referred to as National Board). Those rupture disk manufacturers must meet strict quality and inspection standards and follow prescribed product testing and evaluation protocols. Only after facility certification and the satisfactory submission of product description to and witnessed testing by a member of the National Board, which includes performance testing related to both burst accuracy and flow, can that specific product be offered commercially as ASME Compliant from that particular manufacturing facility.

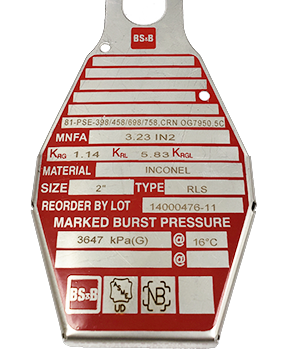

The witnessed testing validates both satisfactory Code-defined burst pressure precision and concurrently, ASME-certified velocity head loss or KR values and the certified minimum net flow area (MNFA) for that size and type of product. When this “single size” methodology is applied, as a general rule the larger the disk nominal size, the lower the corresponding KR value. Alternatively, a “family” certification may be sought by the manufacturer in which case all available sizes of that product type would have the same conservative KR value. A rupture disk device can have a KRG (gas), KRL (liquid) or KRGL (gas or liquid) based on the fluid phase which is expected to open the disk at the instant of overpressure. Those Code-certified values (KR and MNFA) are used by the relief system design engineer in sizing the relief system. Only once certified, may the manufacturer offer that family of products as ASME Compliant. Once requested by the customer, the rupture disk manufacturer is obligated to apply the UD mark of ASME and the NB mark of the National Board, to the disk tag and associated documentation.

The manufacturing facilities themselves must be recertified every 3 years and the product certifications, whether single size or family certified, must be renewed every 6 years in order for the manufacturer to maintain the ability to supply ASME compliant product. Failure of any part of the witnessed certification procedure may result in loss of ability to offer the product as ASME Compliant, carrying the UD and NB symbols as required, until satisfactory resolution is accomplished by appropriate explanation or retest.

One of the most asked questions regarding ASME disks is: Why do ASME disks cost more? The answer is simple. All rupture disks are custom made; we use destructive testing to determine when disk meets the customer’s exact specifications, that testing is done to disks of the same description made by the same operator using the same material and manufacturing the same specification at the same time so that the representative testing is truly indicative of the expected performance of the product being sent to a customer. Per the ASME Code, a disk that is to be UD and NB stamped must undergo additional destructive testing to satisfy the Code requirements and BS&B holds themselves to more stringent accuracy requirements than that stipulated by the Code. Due to the use of additional material and manufacturing time associated with these Code mandated tests, there is an increased cost per disk as those costs are amortized over the number of products ordered. This is the reason why the already quantity dependent pricing is even more so when ASME compliance is required. The other frequently asked question is whether a customer can use the disk from Manufacturer A with a holder from Manufacturer B. The answer is a very emphatic “no” from an code compliance standpoint. While this might seem “convenient” or otherwise advantageous, per the ASME Code a ‘rupture disk device’ consists of a safety head (holder) and a disk and both components must be produced by the same manufacturer. ASME-certified flow data is only valid for disks installed in holders of the same manufacturer and more precisely to only certain holder models made by that manufacturer. In other words, only certain models of BS&B disks can be used with certain models of BS&B holders and be supplied as Code compliant.

For further questions about ASME codes and standards, please Contact BS&B or your local BS&B sales channel partner for more information.

ASME Certified Rupture Disk