Technical Innovations to Mitigate Fugitive Emissions

Continuous improvement in the process industries pursues prevention of fugitive emissions from their facilities as local environmental legislation is becoming more stringent. Rupture disk devices are an important contributor to process safety, and recent technical innovations further assist the process industry with the management of emissions.

Legacy rupture disk technology used an angular seating arrangement between the rupture disk and the holder device. While providing sound pressure relief and a good process seal when installed correctly, poor alignment of the companion flanges might cause cocking of the rupture disk within its holder, which could result in a non-centralized installation, giving rise to less than ideal sealing, possible restrictions of the design flow rate, and diminished rupture disk performance.

Over the decades BS&B’s constant stream of innovations have provided the process industry user with improvement opportunities that offer enhanced rupture disk device performance. BS&B’s Sta-Saf™ range of rupture disks and rupture disk holders introduced a flat seat disk/ holder interface complete with a proprietary bite seal on the process side of the rupture disk holder specifically designed to provide leak tightness above ‘bubble tight’ and even up to a leak rate of 1x10-6 mbar ls-1. Bite seals were also made available on the non-process side of the rupture disk by special request to achieve such enhanced leak tightness on both sides of the disk which can be important after activation.

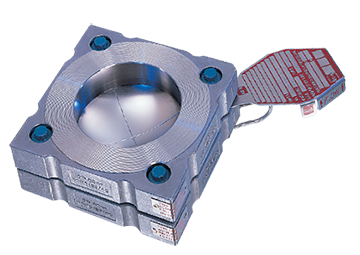

Further development saw the evolution of the pre-torqued SRB-7RS™ range of rupture disk holders which allowed the appropriate clamping force to be applied to the rupture disk via a set of holder mounted cap screws. This clamping arrangement makes the disk performance less vulnerable to the effects of misaligned companion flanges and incorrect torquing of the companion flange studs, reducing the risk of fugitive emissions.

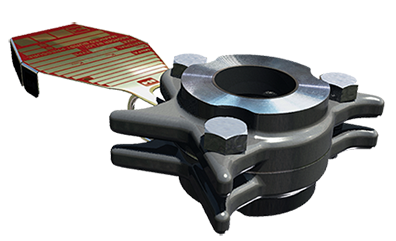

The self-centering SRI-7RS™ followed which features self-centering lugs to ensure that the rupture disk device is centered precisely as the companion flange studs are progressively tightened. This feature ensures that the ASME certified Kr value is reproduced in the field and the rupture disk device is installed optimally. (US and international patents pending.)

In summary, BS&B’s commitment to innovation, from bite seals on flat seated rupture disk holders, through pre-torqued and self-centering rupture disk holders, equipped with torque resistance disk seating area to allow for the use of spiral wound gaskets, have all been focused on improved rupture disk performance and ease of installation to contribute to the process industries continuous improvement initiatives driven increasingly by environmental and sustainability considerations.